Complete Guide to Electrical Materials Pricing

January 10, 2023 12 min read

How to Estimate Electrical Materials Like a Pro | Methods and Tips

The electrical contracting business can be very competitive. That means every electrical estimate you submit must be consistent and accurate. With the constant pricing fluctuation of electrical materials, it can be tough to make sure your bids are competitive and profitable.

We’ll outline some popular electrical bidding methods and show you how to estimate electrical materials so you can keep more of your profit in your business. Follow our tips below.

What is Electrical Materials Estimating?

Electrical materials takeoff is the process of determining which materials you will need to complete the job and the quantities required by a review of the job’s electrical plans. Once you have a list of electrical materials for the job, you can determine the material costs.

Materials make up a large and important part of any electrical estimate. This is especially true for high dollar and high-volume items, e.g. power distribution panel or thousands of feet of copper wire and conduit.

When you’re creating any bid, it’s important to be both accurate and fast.

How Do You Estimate Electrical Materials?

There are many methods estimators use to complete an estimate for the electrical materials used for a job. Here are few commonly used methods along with their pros and cons.

Per Point Method

With the per point method, an estimator assigns a dollar value to each fixture, such as power point, switch, sensor etc., and then counts the total number of those fixtures and multiplies the number to determine the cost estimate. For example, if a job has 80 points and you have chosen $100 per point, you would estimate the job at $8000.

Pro – This is a very fast method of calculating an electrical estimate.

Con – Per Point Method can be too general, which makes it difficult to plan for the complexities within a job. This could put your profit in jeopardy.

Pre-Build Estimating Method

Also known as the Assembly estimating method, this is a way of counting electrical materials by packaging the elements of a single assembly into one unit. You assign a price per unit and again multiply the number of units by the assigned price.

Pro – This method is also very speedy, and it allows more sophisticated takeoffs than the per point method.

Con – Pre-Build Method is essentially a more complex version of the Per Point Method. Because it’s also an averaging method, it doesn’t always provide sufficient detail to account for all the materials, which may again cut into your profit.

Design & Construct Method

In the design and construct method, the electrical contractor is involved with design and implementation of the project. That means that you will create a detailed design from a brief that is supplied by the customer. You must also meet the budget specifications of the project.

Pro – With a design and construct job, you will have the freedom to make choices about the electrical design for a project.

Con – This method of estimating is very complex, because you need to have a lot of knowledge about construction and how the electrical design will affect materials selection as well as labor costs.

Guesstimating Method

This is a method that should never be recommended. (We almost didn’t include it!) If you have ever eyeballed a job and given an estimate that is more of a gut feeling than a reasonable analysis, then you have guesstimated a job. Guesstimating can be wildly inaccurate, and shouldn’t be undertaken by any electrical contractors, even experts.

Quantity Takeoff Method

Quantity takeoff is the process of estimating costs for the electrical materials needed for any job you want to bid on. It’s the process of reviewing the work shown on drawings, plans, and specifications and converting the information to lists of electrical materials that can be priced. Envision the completed work including fittings, hangers, fasteners, devices and cover plates. And as a rule, quantity takeoff excludes other aspects of the job’s total cost, like labor, overhead, and permits.

How to Complete a Quantity Takeoff

- Count the items shown on the electrical drawings. Start with one item, like light fixtures and count all items sheet by sheet with a total for each sheet.

- Calculate the materials you will need to complete the job by marking the plans, item by item.

- Use the takeoff to plan and schedule the work that is necessary for the job.

- Create procurement lists for electrical materials needed for the job.

Exact and comprehensive takeoff is the foundation of a successful bid. Any mistakes at this stage are likely to be exacerbated when you begin to price the job. Using electrical estimating software helps to create and accurately track your electrical materials list so that you can create a bid for submitting to your customer.

What is a Materials List?

Once you have finished your quantity takeoff, you will have a materials list that includes quantities you require for your electrical materials including wire, receptacles, junction boxes, fuses, circuit breakers, fixtures, electrical outlets, panels, and switches. This is the list you will send to your electrical materials supplier.

What is an Audit Trail and Why do I Need One?

An audit trail is a list of the items you have already taken off and counted in your takeoff. An audit trail is indispensable for double checking your estimates. When you’re evaluating electrical estimating software, you should ensure that the software creates a comprehensive and flexible audit trail.

Pro Tips for Estimating Electrical Materials

Here are some tips you should not forget when you’re estimating electrical materials.

- Review architectural drawings in addition to electrical drawings so you have an idea of how working heights and elevations may affect materials pricing and equipment requirements.

- Note whether you are responsible for specialty items like HVAC hookups or low voltage.

- Once you are awarded a job, request quotes for lighting first because these items take longer.

- Ensure that your estimate includes mark-up % so that you can be sure of your profit.

Remember that Mark Up is not the same as Profit. Profit is the amount you make after covering all costs for the job like materials, labor, and overhead like office rentals and salary for your full time (non-electrician) staff.

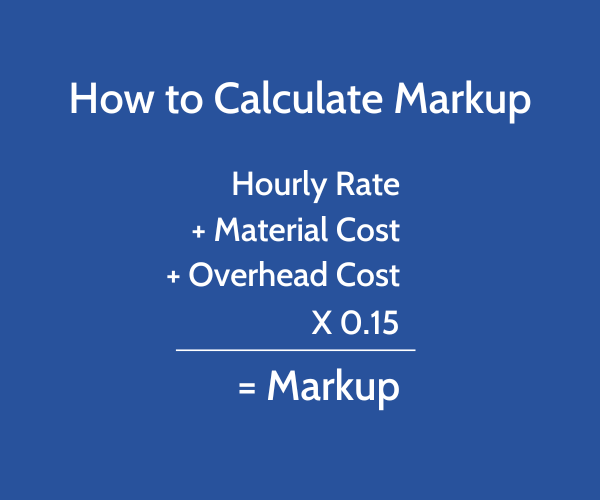

If your ideal profit margin is 15% use the following formula:

Should I use an Electrical Pricing Service?

First, some definitions.

What is Trade Price?

The Trade Price is the non-discounted wholesale price published by the manufacturer. Other terms for trade price include list price, column 3 price, or end column price.

What is Target Price?

The Target Price, also called market price, is an average of prices actually paid by electrical contractors. Generally, the target price includes a cushion of a few percentage points built in. If you use an electrical pricing service like EPIC or EPIC Netpricer, which monitors suppliers all over the country to calculate a national average cost for materials, you’ll be able to keep prices current in your estimating software.

Suppliers may offer a discount on the trade price. Some discounts are specific to a particular item on your materials list, while you may also receive a percentage discount for a group of items.

On the one hand, your supplier knows you and knows your business, BUT you can never be 100% confident you’re getting the best price – especially if your supplier knows they don’t have to compete for your business. Like you, they’re in business to make a profit. Additionally, it may take time for your supplier to get back to you, especially when they’re busy.

The Advantage of Using a Pricing Service

A pricing service provides important functions that help keep your materials costs under control. And pricing services provide instant pricing that comes with the confidence that your pricing service has already done the work of shopping around for you.

- Pricing services are updated regularly so your prices are up to date. Some, like EPIC NetPricer even give you instant access to current pricing.

- Some services give you the option to update your pricing list with files from your local supplier as well as national price lists. Others give you one click access to negotiated pricing from your preferred supplier.

- Gives a benchmark. If you don’t know the average price, it’s impossible to get the best prices from your supplier.

5 Common Electrical Materials Pricing Myths Busted

Here are 5 common misconceptions about electrical materials pricing:

Myth: Prices don’t change very often.

Fact: Prices change millions of times per year, even before the recent surge in electrical materials prices.

Myth: Materials pricing from your local distributor is competitive.

Fact: Some suppliers give competitive pricing when they are aware they are being compared to other suppliers or to the national pricing average.

Myth: Copper materials prices are entirely tied to the commodity market.

Fact: While there is a link between the cost of copper and the cost of wire, it’s not a direct correlation. During volatile times the price spread between different suppliers will be much higher. Some suppliers will price according to their cost, others will price according to the current market.

Myth: Pricing is regional.

Fact: There are pricing variations across the street or across town, rather than by region. The exception is that costs are higher overall in remote areas.

Myth: Pricing is dependant entirely on volume.

Fact: Very large volumes do often get a discount, but you don’t have to run a 500 man shop to get the very best prices.

Summary

The final step in estimating electrical materials should always include a complete review. When you’re creating your bid for submission, make sure you double check details like the customer's name and address, and ensure your materials list has no mistakes. You want to submit a bid that's right on target.

Your electrical bid should be precise and itemized, which will help you if there are revisions to the plans or the staging of the job.

In short, using electrical estimating software to create your estimates can make your job much easier – improving accuracy and profitability. Most electrical estimating software includes templates for bid submission. And software can help you to automate many time consuming parts of the bid process, like markup calculations and subtotals for various stages of the job, so you can complete more estimates in less time and win more jobs.

Electrical contractors use a combination of these strategies to ensure they get the best prices on electrical materials. Once you have your materials list confirmed, you can watch our video on 7 Habits of an Effective Electrical Estimator for tips on making your estimating workflow more effective.

.png?width=2240&height=1260&name=VI%20-%20YouTube%20Thumbnails%20-%20blog%20update%20(Blog%20Banner).png)